|

| February 09, 2016 | Volume 12 Issue 06 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Super-slim film heater is hot prospect for electric car interiors

If you don't want to freeze in your electric car, you have to make a few concessions because heating devours a substantial portion of the power supply. But researchers in Germany have a solution: a highly energy-efficient coated film that produces a broad, radiant heat.

The system, created by engineers and scientist from the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) in Stuttgart, made its debut at the International Motor Show Germany last September.

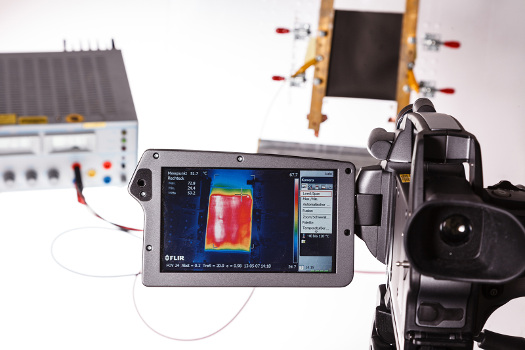

In order to analyze the warming effect of new thin-film heaters for electric cars, researchers connected the films to a power source and monitored them using a thermo camera. [© Photo: Fraunhofer IPA]

In the winter, an electric vehicle's range declines markedly due to the additional energy demanded by the heating system. As opposed to conventional passenger vehicles, which produce excessive amounts of engine heat, electric cars generate next to no heat, so an additional electric heater is definitely required. This is supplied with power by the same battery that provides the engine with energy. "In the most unfavorable case [in winter], you can only drive half the usual distance with the car," says Serhat Sahakalkan, project manager at the Fraunhofer IPA.

Researchers at the IPA have developed a film-based panel heater that quickly provides a comfortable warmth in electric cars and has proven to be -- particularly on short journeys -- more effective than other electric-heater designs. The heating concept is based on a film that is coated with conductive carbon nanotubes (CNTs).

To make it, the researchers spray on a very thin layer of CNT dispersion. "The film is glued to the inner door trim and generates a comfortable warmth there in the area of the armrest within a very short time," Sahakalkan explains. The heater functions in accordance with the Joule principle: When electricity flows through the film, it comes across a natural resistance between the individual nanoparticles. These "collisions" generate heat.

Extremely thin film saves energy and costs

Conventional electric resistance heaters of the type used in electric cars also make use of this principle. Usually, the conductive material used is copper wire, which is embedded in silicone mats, for example. The solution created by the researchers from Stuttgart, however, offers several advantages: While the copper-wire heaters available at present are relatively "bulky" and take up quite some installation space, the film heater consists of a layer of conductive material with a thickness of only a few micrometers. Its flexibility allows it to be applied to a high variety of surfaces and contributes to energy savings and costs due to its low weight.

The CNTs themselves have a low heat storage capacity, so the generated heat is directly released into the environment. As opposed to the wire-based variant, the heat from the film is evenly distributed over the entire material's surface, which considerably increases efficiency. When the driver switches the heating off, the material cools down just as quickly.

"These fast response times are ideal for short distances such as urban trips," Sahakalkan says. The desired heating output can be infinitely adjusted by the user. Even isolated defects do not impair functionality. In wire-based heating systems, for example, even minor breaks in the metal can lead to failure.

One drawback still to be worked out is that in order to evenly apply the film to an arched door trim, for example, the researchers divide it into small modules and then glue them to the door trim in sections. "Slight creases arise at the curvatures, which change the spacing of the electrodes. Even heat distribution would then no longer be ensured," says Sahakalkan.

The experts from Stuttgart intend to simplify this procedure and spray the CNT dispersion directly onto the corresponding vehicle components. "This would make the production process considerably more economical, particularly in comparison to wire-based solutions," Sahakalkan says.

Source: Fraunhofer Institute for Manufacturing Engineering and Automation (IPA)

Published February 2016

Rate this article

View our terms of use and privacy policy